Dealer Spotlight – Standley Batch Systems, Inc.

About Standley Batch Systems, Inc.

Established as a small group of industry craftsmen in 1940, Standley Batch Systems, Inc. has grown into a diverse materials handling plant manufacturing company for the concrete industry. The company’s presence has expanded from Southeast Missouri across North America and beyond.

Standley Batch’s location in Cape Girardeau, Missouri, in the center of the USA, affords ample space to produce and design entire plant structures from start to finish. All Standley Batch plants are made in the USA.

Leaders of the concrete materials handling industry

As leaders of the concrete material handling industry, the company takes pride in its deep-rooted history-shaping materials to fit many manufacturing specialists’ needs – no matter their field. While Standley Batch’s services are primarily associated with concrete paver and concrete block plants, precast and prestressed concrete, ready-mix concrete plants, dry-mix concrete plants, and bagging plants, they’ve worked with a variety of material producers to develop solutions that exceed expectations.

Suppliers of Rapid concrete mixers and spare parts

Standley Batch are proud suppliers of the Rapid Mixer line to complete full-service plants, from aggregate to cement to the finished mixed product. Built for durability and longevity, the company carries a large stock of genuine Rapid spare parts, most of which include same-day dispatch to reduce plant downtime. If you are interested in adding a Rapid mixer to your existing plant or ready for a new plant build, Standley Batch offers smart solutions for today’s needs, tomorrow’s growth, and your business’s success.

Featured Standley Batch Systems, Inc. project: Tindall Precast, Spartanburg, SC

Standley Batch Systems was proud to partner with Tindall Precast of Spartanburg, South Carolina for their new concrete plant creation. Tindall required a high-quality mixing technology and the company knew a Rapid mixer was the solution.

Standley Batch supplied and installed a Rapid R4000 pan concrete mixer with a Rapid Jetwash, high pressure mixer washout system.

The Rapid R4000 is the largest capacity pan concrete mixer offered by Rapid and outputs 4m3 per batch (approximately 120m3 per hour). The mixers high capacity makes it ideal for readymix and precast applications. Featuring chill cast wall and floor tiles, wear sleeves and paddles and heavy duty discharge door mechanisms, the mixer is robust and hard wearing.

The Rapid Jetwash is a fully galvanised, self-contained high pressure mixer washout system used for effective clean out of concrete mixers. The Jetwash offers fast and effective cleaning, with each cleaning system taking just four minutes and one unit is capable of cleaning up to four mixers.

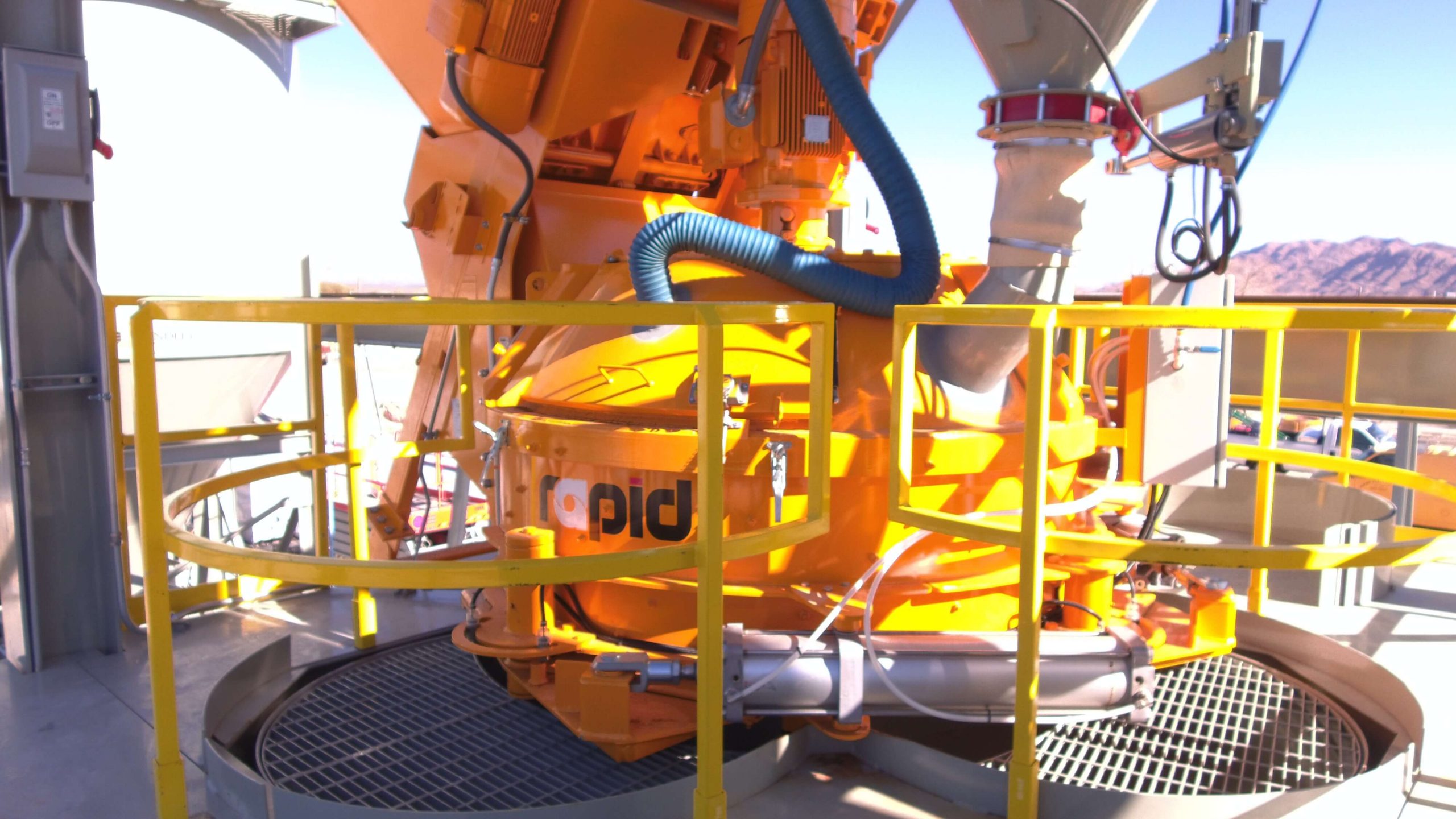

Featured Standley Batch Systems, Inc. project: Olson Precast, Las Vegas, NV

Olson Precast needed smart space-saving solutions to save time and money. Standley Batch suggested the Rapid RP750 planetary concrete mixer with Rapid skip hoist to provide fast, dependable lifting of the aggregates to the Rapid mixer. This system proved to be compact, space-saving, reliable and the quality of the equipment will serve them for many years.

The Rapid RP750 planetary concrete mixer outputs 0.75 m3 per batch (23m3 per hour). The mixers offers star mixing motion, produces a thoroughly homogeneous mix, making it ideal for precast and semi-dry coloured concrete applications. As with all Rapid mixers, the Rapid planetary features hard wearing chill cast wall and floor tiles, wear sleeves and paddles and heavy duty discharge door mechanisms.

Contact Standley Batch Systems, Inc.

Contact Mark Hoffman at (800) 325-8084 markh@standleybatch.com or visit standleybatch.com.